What does the building code say about notching a top plate

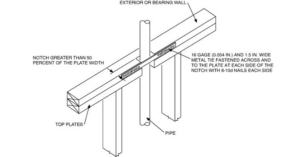

Building Code Requirements for a 1 ½” Galvanized Metal Tie When Notching a Top Plate More Than 50% (R602.2.3.1 [IRC R602_6_1] Drilling and Notching of Top Plate)

Introduction In residential and light commercial wood-framed construction, top plates serve a critical role in distributing loads and maintaining the structural integrity of walls. However, it is often necessary to notch top plates to accommodate plumbing, electrical, or mechanical systems. According to modern building codes, when a top plate is notched more than 50% of its width, specific reinforcement methods must be used to ensure continued structural performance. One such requirement is the installation of a 1 ½” galvanized metal tie.

Understanding Top Plate Notching: Notching occurs when part of the top plate is cut away to provide clearance for utilities or other construction elements. The International Residential Code (IRC) and other local building codes provide strict guidelines on how notching should be handled to prevent compromising the structural integrity of the wall.

Building Code Specifications According to IRC Section R602.6.1 (or the equivalent in other building codes):

- A top plate may be notched to accommodate mechanical, electrical, or plumbing systems, but if the notch exceeds 50% of the top plate’s width, additional reinforcement is required.

- The required reinforcement consists of a galvanized metal tie that is a minimum of 1 ½” wide and 16-gauge thick.

- The metal tie must be installed across the notched area and must extend at least 6 inches beyond both sides of the notch.

- It must be fastened with a minimum of (8) 10d nails or equivalent fasteners, evenly spaced to ensure a secure attachment to the remaining portions of the top plate.

Purpose of the Metal Tie The primary function of the galvanized metal tie is to restore the structural integrity of the top plate by redistributing loads that would otherwise be interrupted by the notch. This helps to:

- Maintain the lateral and vertical load-bearing capacity of the top plate.

- Prevent potential failure under wind, seismic, or gravity loads.

- Ensure compliance with building codes and avoid future structural issues.

Installation Guidelines

- Measure the Notch – Determine the extent of the notch and confirm if it exceeds 50% of the plate’s width.

- Select the Proper Metal Tie – Use a galvanized 16-gauge steel tie with a width of at least 1 ½”.

- Position the Tie – Center the metal tie over the notch, ensuring that it extends at least 6 inches beyond each side of the cut.

- Secure the Tie – Use at least (8) 10d nails or equivalent fasteners to attach the tie to the top plate.

- Inspect for Compliance – Ensure that the installation meets the required code specifications and passes any necessary inspections.

Conclusion Notching a top plate is often unavoidable in construction, but exceeding the 50% threshold necessitates reinforcement to maintain the structure’s integrity. Installing a 1 ½” galvanized metal tie is a straightforward and effective solution that complies with building codes while ensuring long-term durability and safety. Always refer to the latest version of the IRC or local codes for precise requirements and consult with a structural engineer if necessary.

Our Construction company is Servicing Southeast Michigan, Detroit and the Tri-County area Wyane, Oakland and Macomb;

Our Construction company is Servicing Southeast Michigan, Detroit and the Tri-County area Wyane, Oakland and Macomb;