Wood Wall Framing Terms and description of every component

Wooden stud framing is one of the most widely used techniques in residential and commercial construction due to its cost-effectiveness, ease of use, and adaptability. This article explores the anatomy of a wall constructed with traditional wood studs and delves into the common nomenclature used to describe its components.

Wooden stud framing is one of the most widely used techniques in residential and commercial construction due to its cost-effectiveness, ease of use, and adaptability. This article explores the anatomy of a wall constructed with traditional wood studs and delves into the common nomenclature used to describe its components.

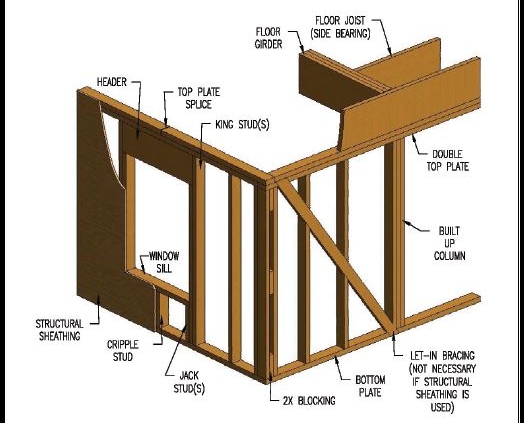

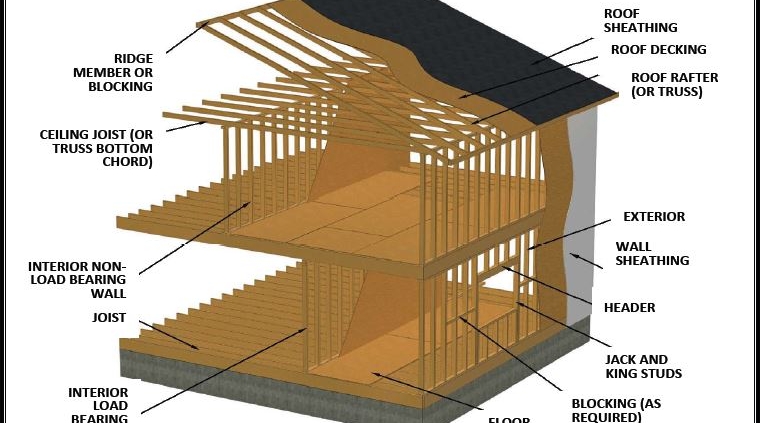

Basic Anatomy of a Wood Stud Wall

A wood stud wall is typically composed of several essential elements that work together to provide structural support, insulation, and protection against the elements. These elements can be grouped into the following categories:

- Top Plate

The top plate is a horizontal wooden beam that runs along the uppermost part of the wall. It provides a surface to attach the wall to the roof system or upper floor. There are usually two top plates, a primary and a secondary plate, stacked on top of one another for added strength and stability. - Bottom Plate (Sole Plate)

The bottom plate, or sole plate, is the horizontal board that rests on the foundation or floor slab. It serves as the base of the wall frame, connecting the vertical studs to the floor. The bottom plate is typically anchored to the floor with nails or bolts to prevent the wall from shifting. - Studs

Vertical wooden members that form the core of the wall’s framework. Studs are evenly spaced (usually 16 or 24 inches apart, center to center) and provide the main structural support for the wall. These studs also serve as anchor points for attaching drywall, exterior sheathing, and insulation. The most common size for studs is 2×4 inches, although 2×6-inch studs may be used in some cases for added strength or to accommodate thicker insulation. - Header

A header is a horizontal structural member placed above door or window openings in the wall. Its purpose is to bear the load from the weight above the opening, transferring it to the surrounding studs. Headers are typically made from larger lumber or a combination of materials, such as engineered wood products, depending on the size of the opening. - Cripple Studs

Cripple studs are short vertical studs installed above or below window and door openings. They help support the header and provide structural continuity to the wall framing. When located above a window or door, they are called “upper cripples,” and when placed below the opening, they are called “lower cripples.” - King Studs

King studs are the full-length vertical studs located on either side of a door or window opening. They provide the primary vertical support for the wall framing around the opening and work in conjunction with the header to distribute weight. - Jack Studs (Trimmer Studs)

Jack studs, also known as trimmer studs, are shorter vertical studs located next to the king studs and positioned to support the header. They help transfer the load from the header to the bottom plate and help reinforce the opening. - Sheathing

The exterior covering, typically made from plywood or oriented strand board (OSB), is fastened to the outer side of the wall framing. Sheathing provides additional structural integrity and helps to prevent lateral movement or swaying of the wall. It also acts as a surface to which the exterior cladding (such as siding or brick veneer) is attached. - Insulation

Between the studs, insulation materials such as fiberglass batt, foam board, or spray foam are installed to improve the wall’s thermal resistance and reduce energy consumption. Insulation is an integral part of creating comfortable living spaces and enhancing the wall’s overall performance. - Drywall (Interior Finish)

Inside the home, the wall is usually finished with drywall (also known as gypsum board), which is attached to the studs with screws or nails. Drywall provides a smooth surface for interior finishes, such as paint or wallpaper, and also serves as a fire barrier.

Common Terminology and Nomenclature

The nomenclature of a wood stud wall varies slightly depending on regional practices or specific building codes, but the general terms mentioned above are widely recognized. In addition to the primary components, other specialized terms are used in framing to ensure clarity and consistency:

- Stud Spacing: The distance between adjacent studs, typically 16 or 24 inches apart. This spacing affects both the strength and the insulation capacity of the wall.

- Nailers or Blocking: Horizontal pieces of wood placed between studs to provide additional support for fixtures, such as cabinets, shelves, or appliances. These members are also used to anchor other systems, like electrical wiring or plumbing.

- Corner Bracing: In certain structural configurations, corner bracing may be added to improve the stability of the wall. These braces are typically placed diagonally in the corner spaces to resist lateral forces, such as wind or seismic activity.

- Sill Plate: The sill plate is the horizontal timber or board that sits atop the foundation, directly beneath the bottom plate, and helps to anchor the wall to the building’s foundation.

- Fireblocking: In multi-story structures, fireblocking is used to seal off gaps in framing to limit the spread of fire within wall cavities. This is typically made from fire-resistant materials and installed at various points in the wall.

Conclusion

The wall framed with traditional wood studs forms the backbone of many buildings and serves multiple roles, including providing structural integrity, offering insulation, and creating spaces for wiring, plumbing, and finishes. Understanding the anatomy and terminology of stud walls is crucial for anyone involved in the construction or renovation process, whether you’re a homeowner, builder, or designer. With a solid foundation in the key components of wood stud framing, it’s easier to make informed decisions about construction materials, methods, and performance.

Our Construction company is Servicing Southeast Michigan, Detroit and the Tri-County area Wyane, Oakland and Macomb;

Our Construction company is Servicing Southeast Michigan, Detroit and the Tri-County area Wyane, Oakland and Macomb;